Yadkin River Water Supply Project

Yadkin River Water Supply Project

Background:

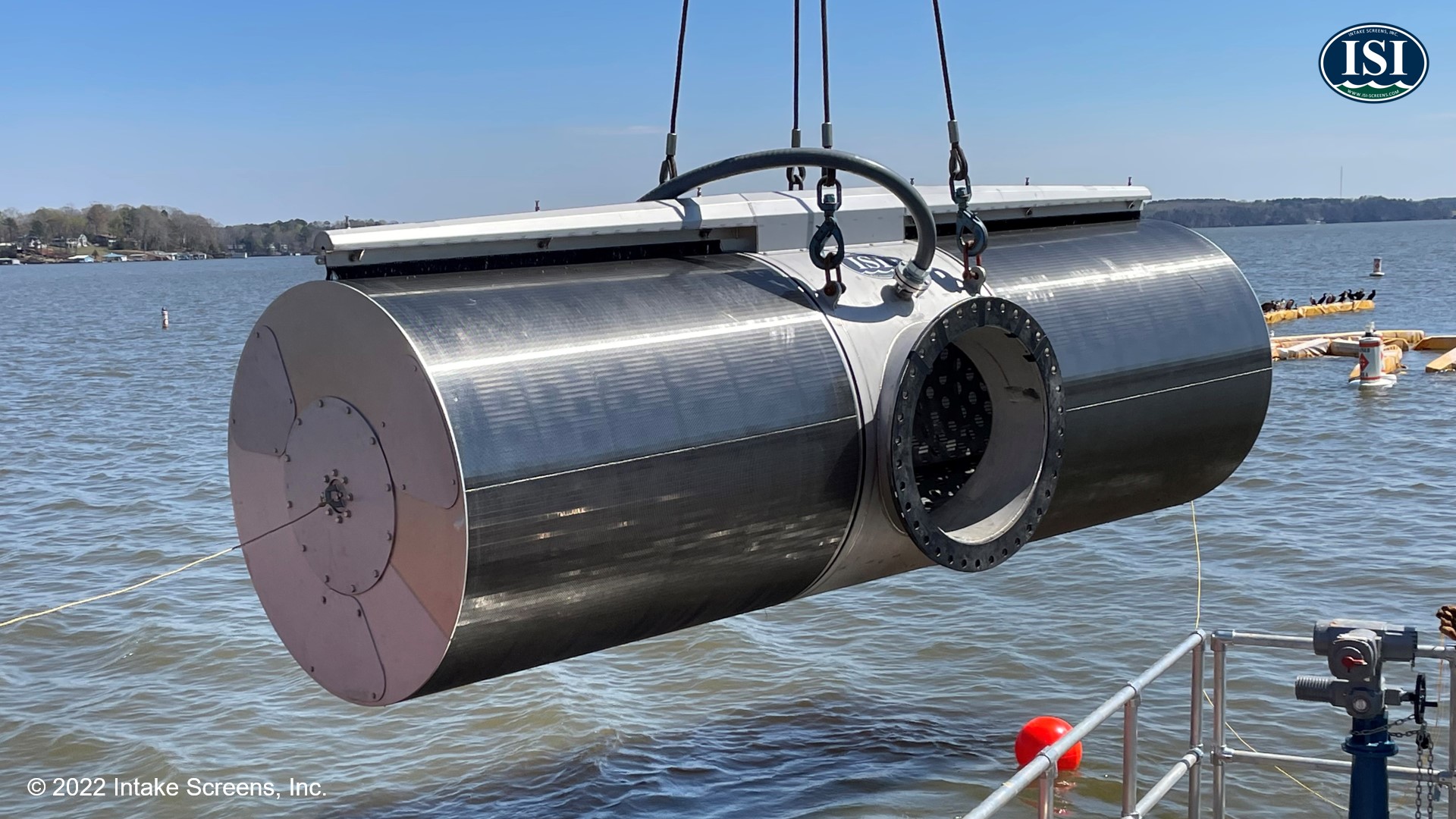

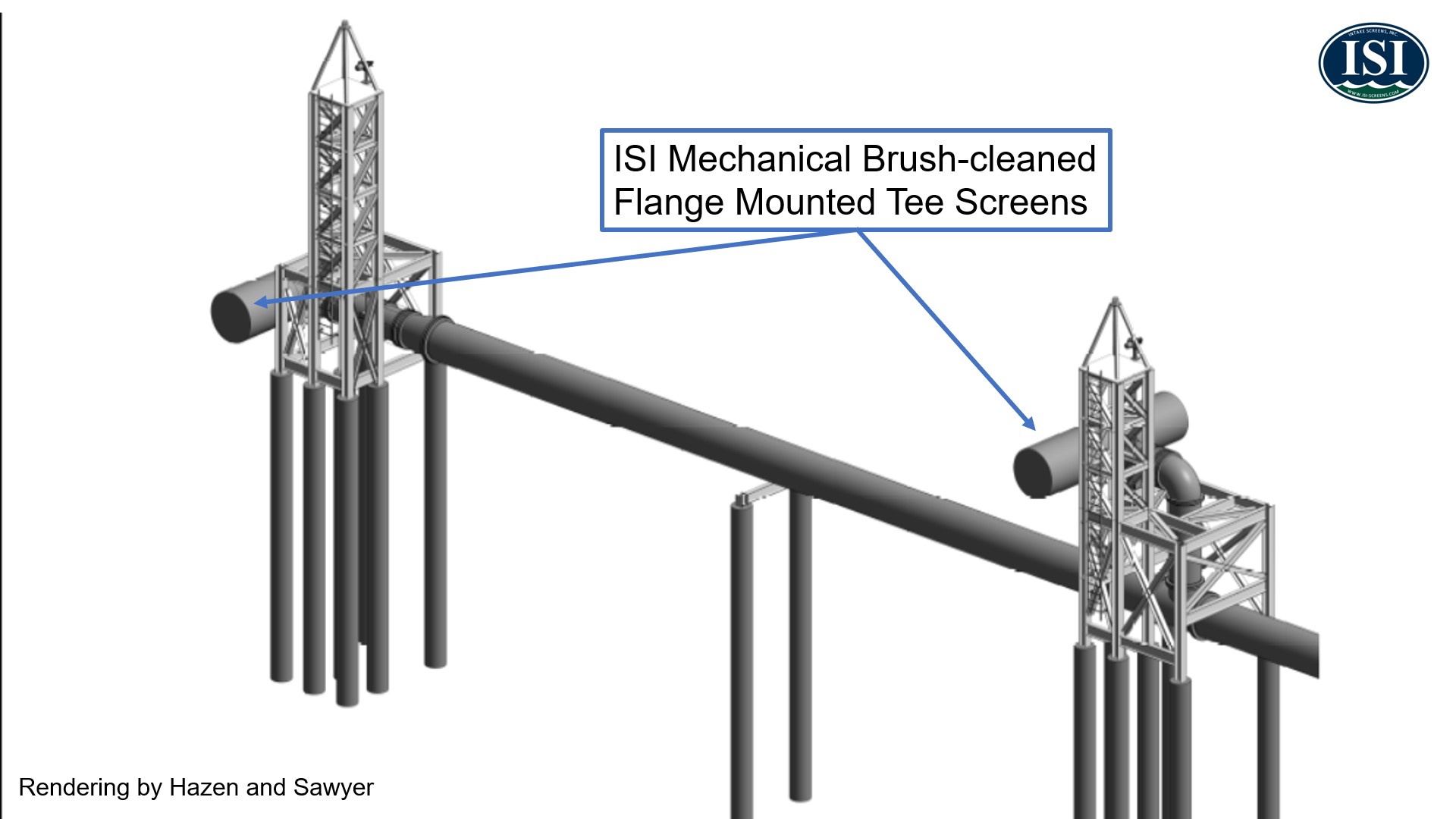

The Yadkin Regional Water Supply project includes construction of a new water intake and pump station on Lake Tillery in Norwood, NC as well as pipelines to distribute this water to municipal users in the Yadkin basin. The project provides a sustainable supply of water to meet this growing region’s current and future water needs. The project incorporated two ISI flange mounted mechanical brush-cleaned tee screens on an intake pipe extending out into the lake. The screens are located 370 feet (113 m) and 480 feet (146 m) offshore in 14 feet (4.3 m) and 30 feet (9.1 m) of water, respectively, and have gates to allow selective withdrawal from either screen. The selective withdrawal capability allows operators to withdrawal high quality water and reduce downstream water treatment costs.

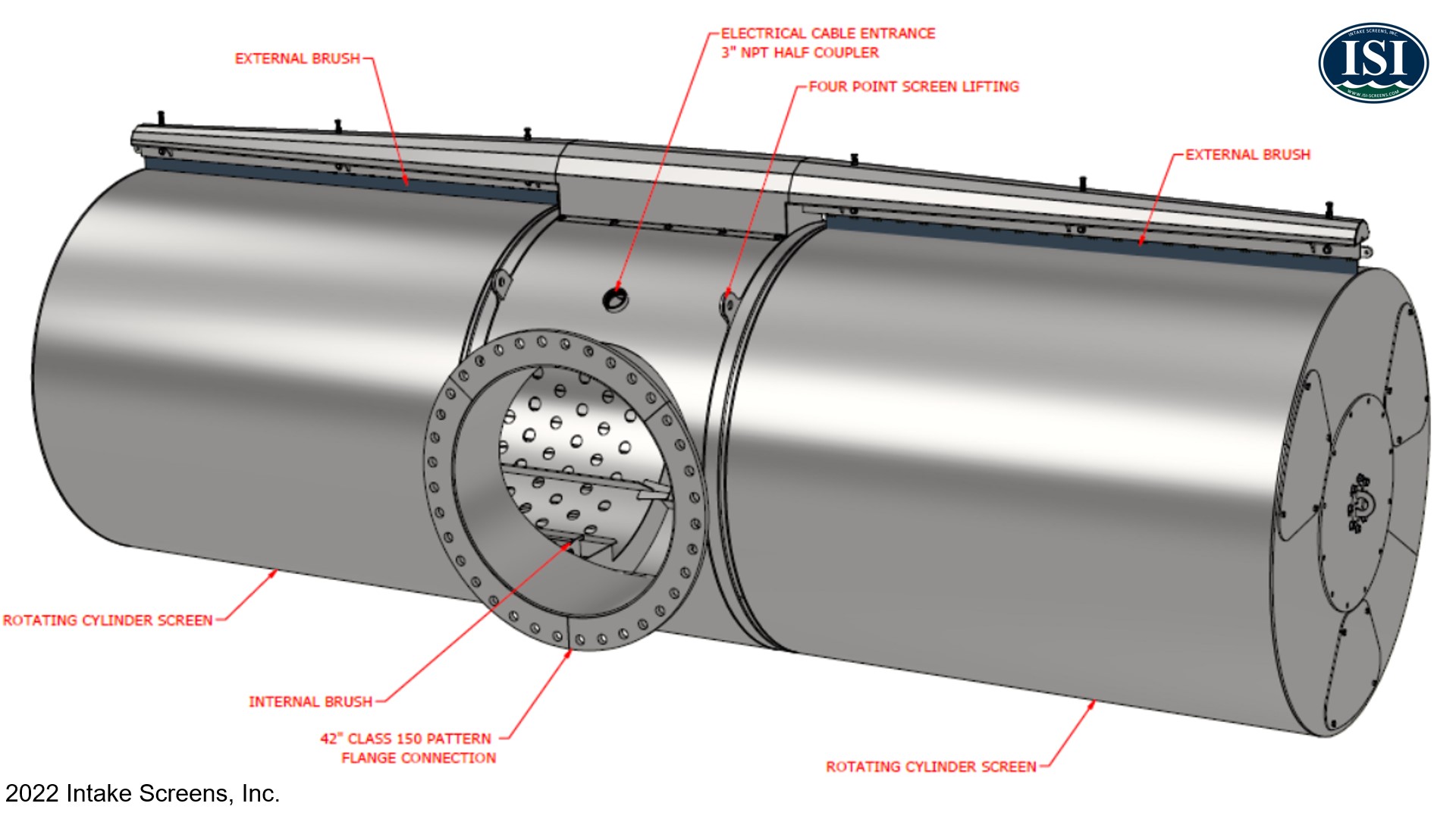

ISI designed and fabricated two T72-90EA-F flange mounted mechanical brush-cleaned tee screens for this project. Each T72-90EA-F screen is fabricated from type 304 stainless steel and measures approximately 19.5 feet (5.9 m) in overall length and contain two wedge wire cylinders measuring 72 inches (1.8 m) in diameter and 90-inches (2.3 m) long. The wedge wire material has a 3.175-mm slot opening and 1.75-mm wire width to create a 64% open area. Each screen has 283 ft² (26.3 m²) of screen surface area and the two screens provide a maximum flow rate to the pump station of 90 cfs (58.2 MGD, 9,174 m³/h) at a 0.5 ft/s (0.15 m/s) through-screen velocity. The brush cleaning system rotates the wedge wire cylinders between external and internal brushes using the provided electric drive assembly. The screen was designed for ease of inspection and maintenance by including a diver access hatch for the screen central manifold and access plates for the internal brush and drive assembly. The screen brush cleaning system is operated from an onshore control panel provided by ISI.

Benefit of ISI System

ISI's flange mounted mechanical brush-cleaned tee screens provide the following key advantages at this site:

- The mechanical brush-cleaning system keeps the wedge wire screen surface clean and free of debris and fouling organisms and ensures reliable water withdrawal.

- The mechanical brush-cleaning system operates without potential for visual impacts or boater safety concerns that are sometimes associated with other cleaning technologies (e.g., airburst cleaning systems).

- The electric brush-cleaning system allows the screens to be provided with an active cleaning system at this offshore location which may be infeasible with other cleaning technologies.

- The screen system was designed for offshore inspection and maintenance without requiring removal of the screens.

Owner:

Union County Public Works

Engineer(s):

Hazen and Sawyer

General Contractor:

Garney Construction, Inc.

Location:

Lake Tillery, Norwood, NC

Year Installed:

2023

Slot Size:

3.175 mm

Screen Model:

T72-90EA-F

Drive System:

Electric

Industry:

Municipal

Water Body:

Lake

Flow Rate:

90 cfs (58.2 MGD, 9,174 m3/h)

Screen Type:

T Screens (dual cylinders)

Retrieval Systems:

Fixed Flange Connection

Number of Screens:

2

Back To All Projects

Back To All Projects