M&T Ranch Irrigation and Wetland Diversion

M&T Ranch Irrigation and Wetland Diversion

Background:

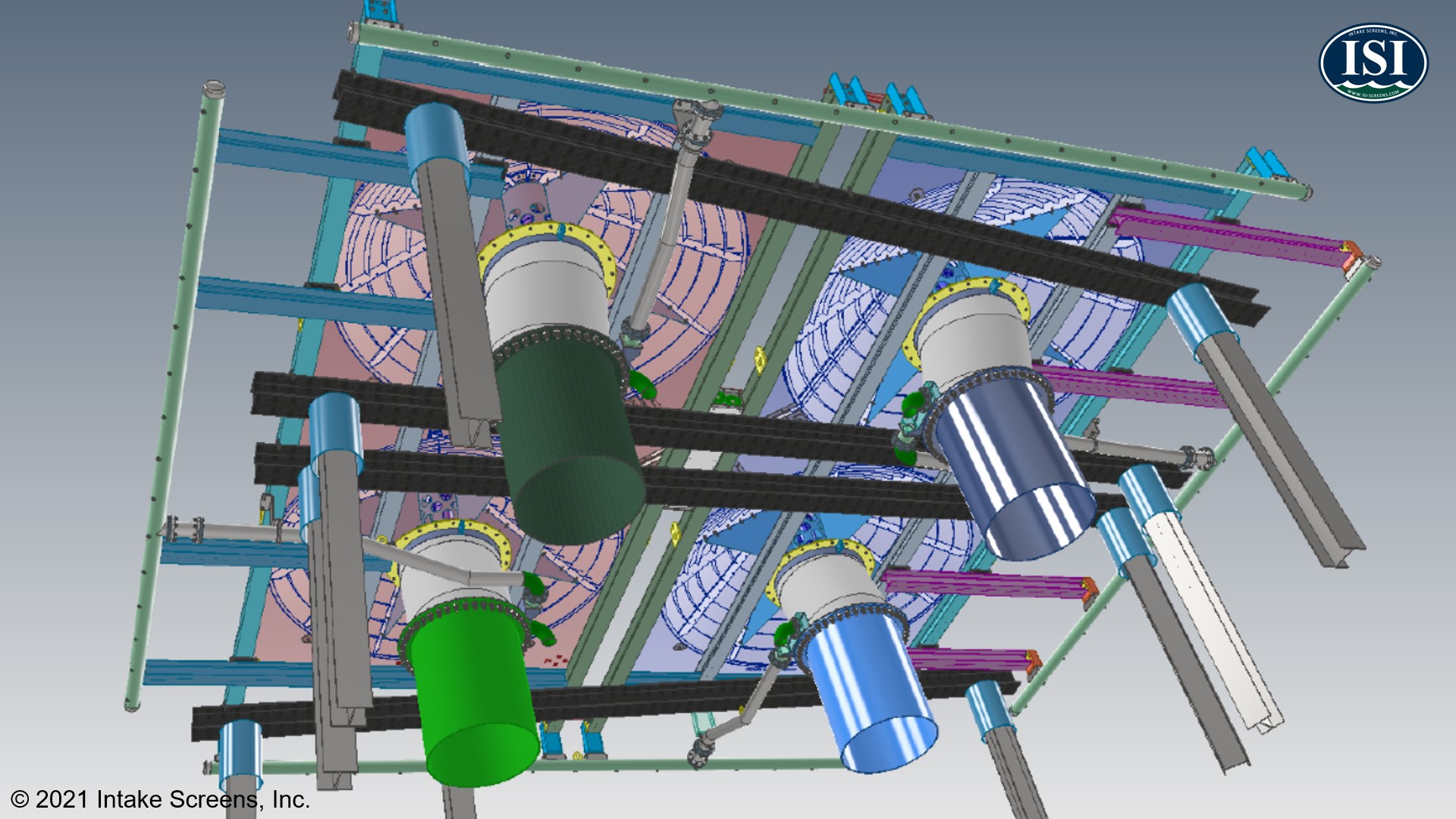

This ISI design-build project involved replacement of four existing airburst cylindrical wedge wire tee screens with four new mechanical brush-cleaned cone screens to protect the intake from an encroaching gravel bar that threatened reliable operation of the intake. This critical intake supplies water to thousands of acres of farmland as well as wetlands owned and managed by state and federal agencies for migratory waterfowl. The project is located on the East Bank of the Sacramento River in California, downstream of the confluence of Big Chico Creek.

ISI designed, manufactured, and installed a mechanical brush-cleaned cone screen system at the site. The new design allowed for the raising of the screen elevation within the water column while continuing to meet state and federal fish screening criteria without a reduction in intake capacity. The design included reuse of the existing pump station and intake pipe and repurposing of the existing airburst system to resuspend sediment along the perimeter of the new cone screen support system. The installed cone screens are model C168-48EA which have a cone shaped wedge wire screen that measures 14-foot (4.3 m) in diameter at the base and 4-foot (1.2 m) high to provide 181.3 ft² (16.8 m³) of screen surface area per screen and a capacity of 57.9 cfs (37.4 MGD, 5,902 m³/h) at a 0.33 ft/s (0.1 m/s) approach velocity. This screen system was designed to meet the total diversion flow rate of 120 cfs (77.6 MGD, 12,233 m³/h) at an average approach velocity of 0.33 ft/s (0.1 m/s) based on a 30-inch (0.76 m) screen submersion depth. Each type 304 stainless steel screen assembly has a submersible electric drive unit, output bush cross, and brush arms. The support structure components were fabricated out of carbon steel and epoxy coated with the exception of the air burst piping which was fabricated out of type 304 stainless steel. A riser ring can be installed between the cone screen and base to provide vertical adjustment to the screen submergence depth.

Benefit of ISI System

Acting as the design-builder, ISI was able to deliver this challenging retrofit project on time and within budget. ISI's brush-cleaned cone screen system provides the following key advantages at this site:

- The conical screen shape provides a large, submerged screen surface area allowing this facility to withdraw its design capacity year-round.

- The brush cleaning system ensures that the screen surface will remain free of debris and fouling organisms and therefore maintain compliance with state and federal fish protection requirements and reliably source water to the facility.

- The repurposed airburst system resuspends sediment around the screen system and allows it to move downstream with the river flow.

- Installation of riser rings between the cone screens and the base allow for vertical adjustment to the screen system if required in the future.

Owner:

Llano Seco/M&T Ranch

Engineer(s):

Intake Screens, Inc.

General Contractor:

Intake Screens, Inc.

Location:

Sacramento River, Chico, CA

Year Installed:

2021

Slot Size:

1.75 mm

Screen Model:

C168-48EA

Drive System:

Electric

Industry:

Irrigation

Water Body:

Stream/River

Flow Rate:

120 cfs (77.6 MGD, 12,233 m³/h)

Screen Type:

Cone Screens (conical)

Retrieval Systems:

Fixed Flange Connection

Number of Screens:

4

Back To All Projects

Back To All Projects