Greenidge Generation Cooling Water Intake

Greenidge Generation Cooling Water Intake

Background:

The Greenidge Generation facility, owned by Greenidge Generation Holdings, Inc., is both a power generator and bitcoin mining facility. This gas fired power plant uses once-through, non-contact cooling as a part of the Rankine cycle to generate electricity. Once-through cooling water is withdrawn from Seneca Lake using an offshore intake system. As a part of meeting Clean Water Act §316(b) and New York State Commissioner Policy 52 requirements, the facility decided to install a 0.5-mm slot size wedge wire screen system with through-screen velocities of 0.5 ft/s (15 cm/s) or less. The combination of the fine slot size and low approach and through-screen velocities screen provides a level of protection to all life stages of fish, from early life stage eggs and larvae through juveniles and adults. The screen system installed at Greenidge Generation is the largest 0.5-mm (0.02-in) slot size wedge wire fish protection screen system anywhere in the world.

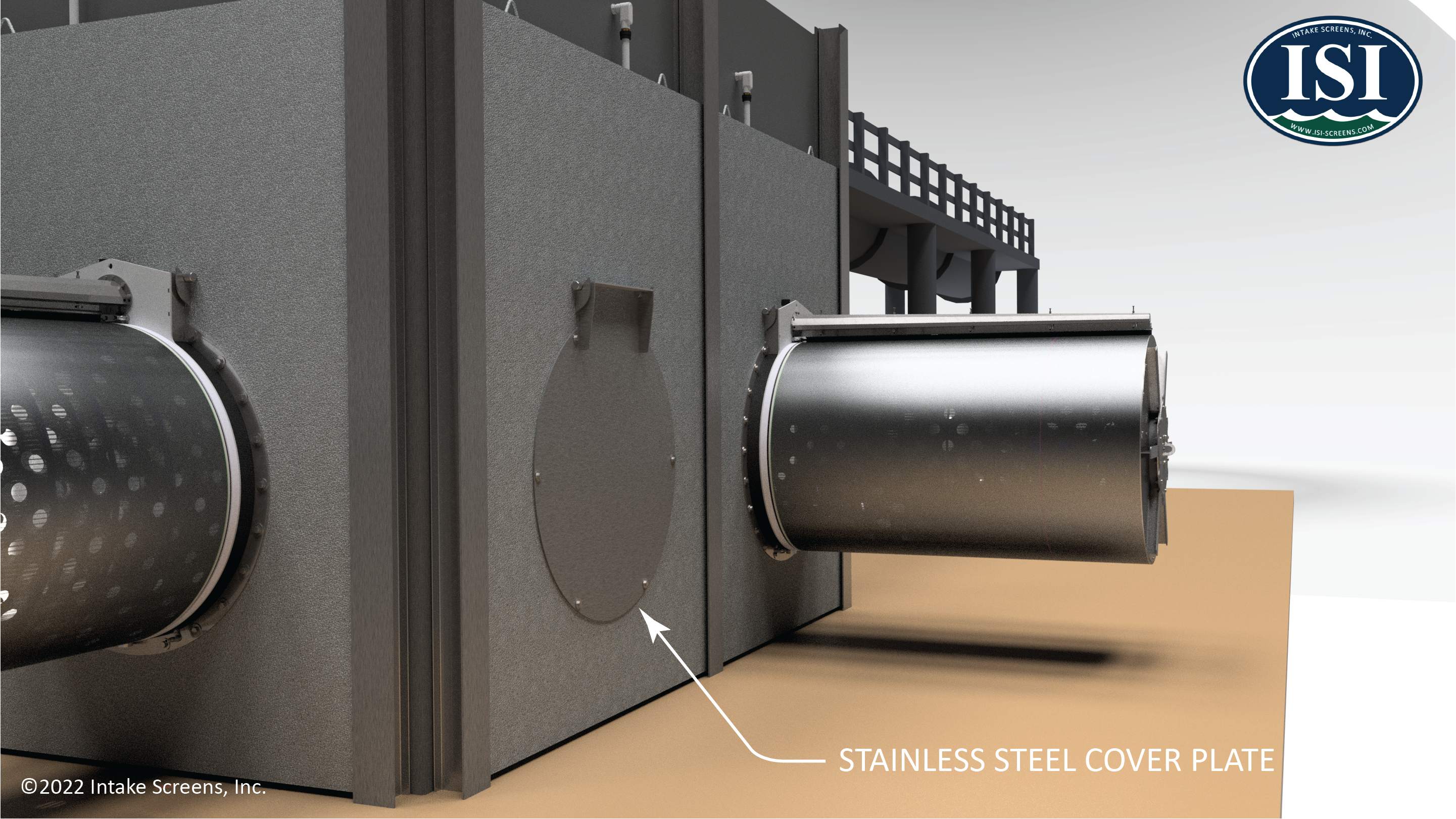

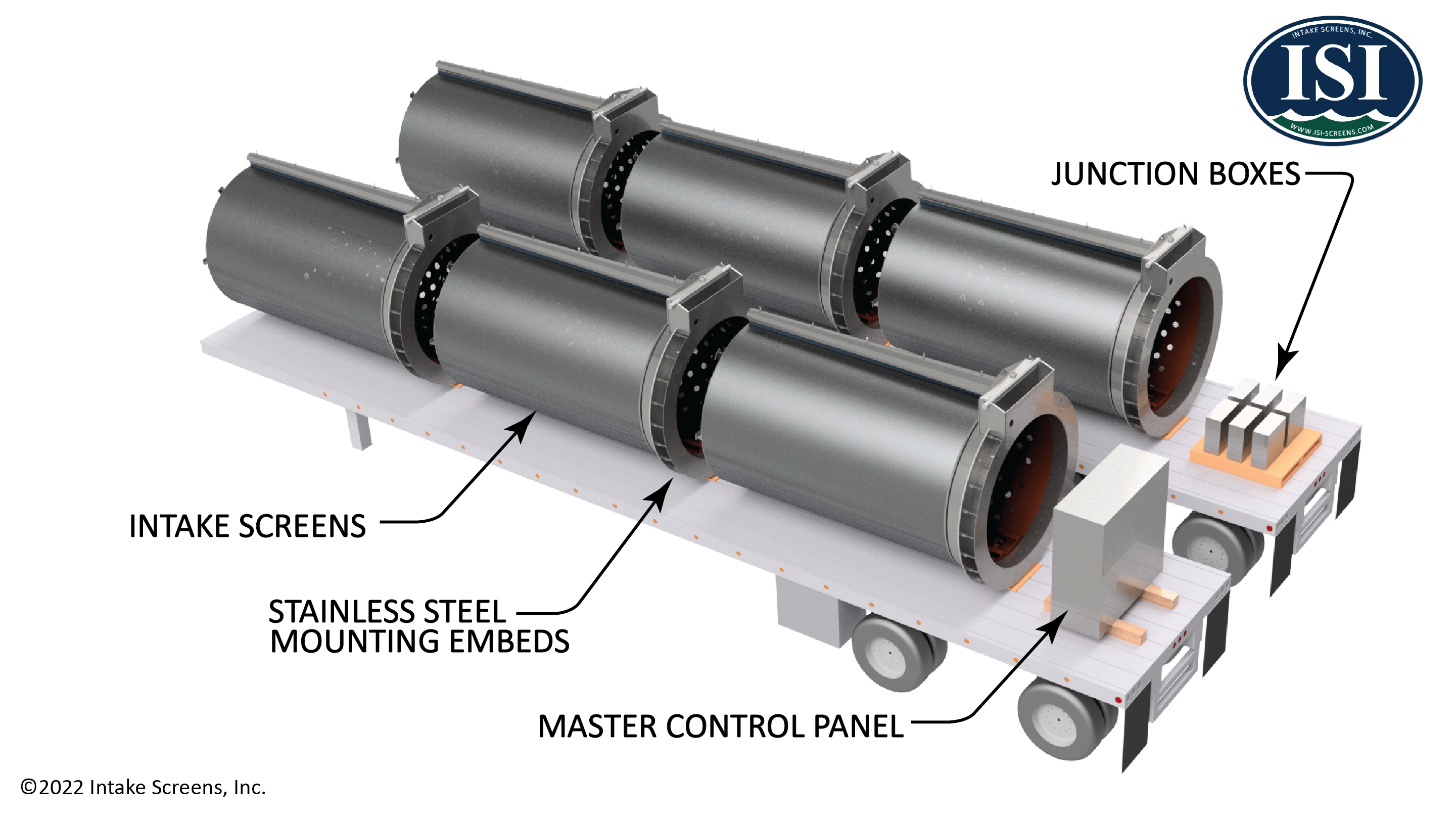

ISI designed and fabricated six (6) D83-132EA-F screens for this project, each measuring 83 inches (2.1 m) in diameter and 132 inches (3.4 m) in length and equipped with an electric drive internal and external brush cleaning system. Each ISI screen unit is connected to an ISI supplied stainless steel embed which includes a hook and pin feature for self-alignment of the flange bolt holes for ease of screen installation and removal. The wedge wire screen area per screen unit is 239 square feet (22.2 m2), resulting in an a through-screen velocity of 0.48 fps (24.4 cm/s) at the maximum flow rate of 151 cfs (98 MGD; 15,445 m3/h) for the six screens. Due to the 22% open area of the 0.5-mm (0.02-in) slot screen material, the approach velocity at the screen surface is just 0.11 ft/s (3.4 cm/s).

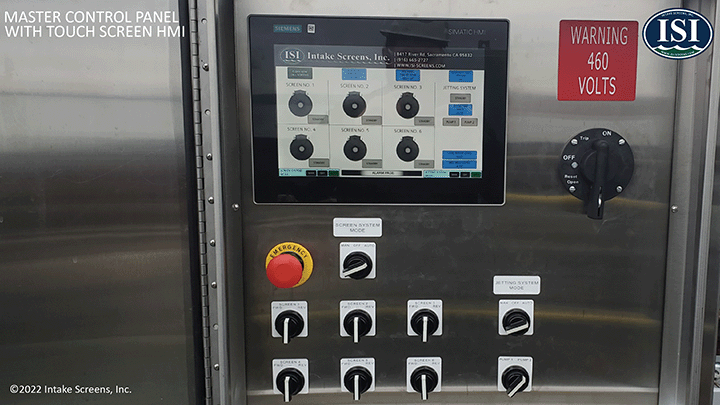

To eliminate fouling organism colonization, including invasive zebra and quagga mussels, of the non-brush-cleaned surfaces inside the screens, a thermal copper spray was applied to the internal suction pipe. To reduce potential accumulations of aquatic vegetation on the external brush and limit invasive mussel shell accumulations under the screen, a water jetting system was included with the screen system. The water jetting system includes a jetting nozzle installed on each side of the external brush and two nozzles installed below the screen. The jetting system pressurizes a total of 24 jetting nozzles using two, 60 hp (44,742 watt) submersible pumps which alternate duty and can be removed on a slide rail system with the remaining pump able to pressurize the water jetting system. A water level differential monitoring system was also included to trigger an automatic “clean-now” and “jet-now” event when an operator defined water level differential is measured. The mechanical brush cleaning and water jetting operations can be manually or automatically controlled by the Master Control Panel provided by ISI and located on the intake screen deck as well as a remote control panel located in the facility’s main control room.

Benefit of ISI System

ISI's Greenidge Generation facility screen system includes the following key features and benefits to address site-specific challenges:

- The mechanical brush cleaning system allows the use of 0.5-mm fine slot openings to provide a high level of fish protection.

- The cylindrical screen shape provides a large screen surface area in a small project footprint.

- The hook and pin flange mounting feature provides a simple and cost-effective screen mounting system that supports efficient screen installation and removal.

- The jetting system provides additional protection against 1) potential mass uprooted aquatic vegetation events which are known to occur with storm events at this site, and 2) deposition and accumulation of invasive mussel shells below the screens.

- The water level differential system provides automation of screen cleaning and jetting system operation to increase intake reliability.

Owner:

Greenidge Generation Holdings, Inc.

Engineer(s):

Intake Screen, Inc. and Bidco Marine Group

General Contractor:

Bidco Marine Group

Location:

Seneca Lake, Dresden, NY

Year Installed:

2022

Slot Size:

0.5 mm

Screen Model:

D83-132EA-F

Drive System:

Electric

Industry:

Electrical Generation

Water Body:

Lake

Flow Rate:

151 cfs (98 MGD; 15,445 m3/h)

Screen Type:

Drum Screens (single cylinder)

Retrieval Systems:

Fixed Flange Connection

Number of Screens:

6

Back To All Projects

Back To All Projects