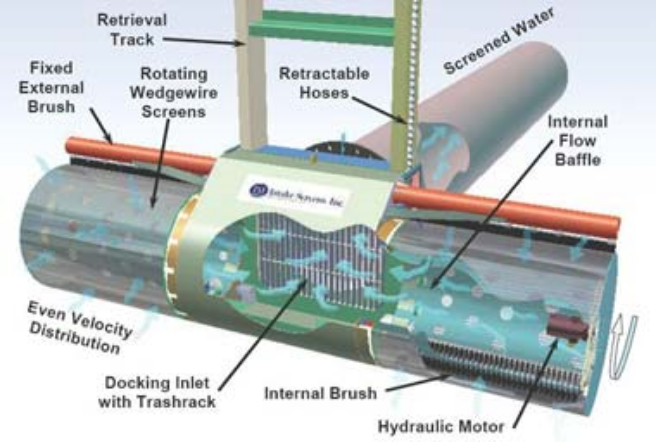

BRUSHED CYLINDER FOR SUBMERGED INTAKES

Summary:

• Designs for shallow water, tidal estuaries, and silty conditions

• Protects fish from entrainment or impingement

• Protects pump from clogging debris

• Protects downstream filtration and irrigation equipment

Key Features

• Screen can be used even if not fully submerged

• Positive brushing action prevents debris buildup, sedimentation, and bio-fouling

• Cone shaped design is very strong and hydraulically efficient

• Easy to install and remove onto various base designs

• Internal flow baffle distributes flow evenly across the screen surface

• Marine-duty hydraulic drive motor rotates cleaning brushes

• Control panel allows user defined cleaning cycles

Control & Power Features

• Minimal power requirements

• Solar power options available

• Interfaces with customer’s SCADA controls for remote monitoring and control

• Control panels to match customers equipment

• Wedgewire slot width options from 1 mm to 9 mm

• Screen design and construction for extreme design loads

• Screen base diameters up to 15 feet to meet application needs

Options & Customization

• Wedgewire slot width options from 0.5 mm to 9 mm

• Design for extreme conditions, including ice, debris, currents and hydrostatic forces

• Control panel options to match customer’s equipment if necessary

• Screen lengths and diameters to meet application needs

• Screen lengths and diameters to meet application needs