Sears Turbine Drive Screen

Sears Turbine Drive Screen

Background:

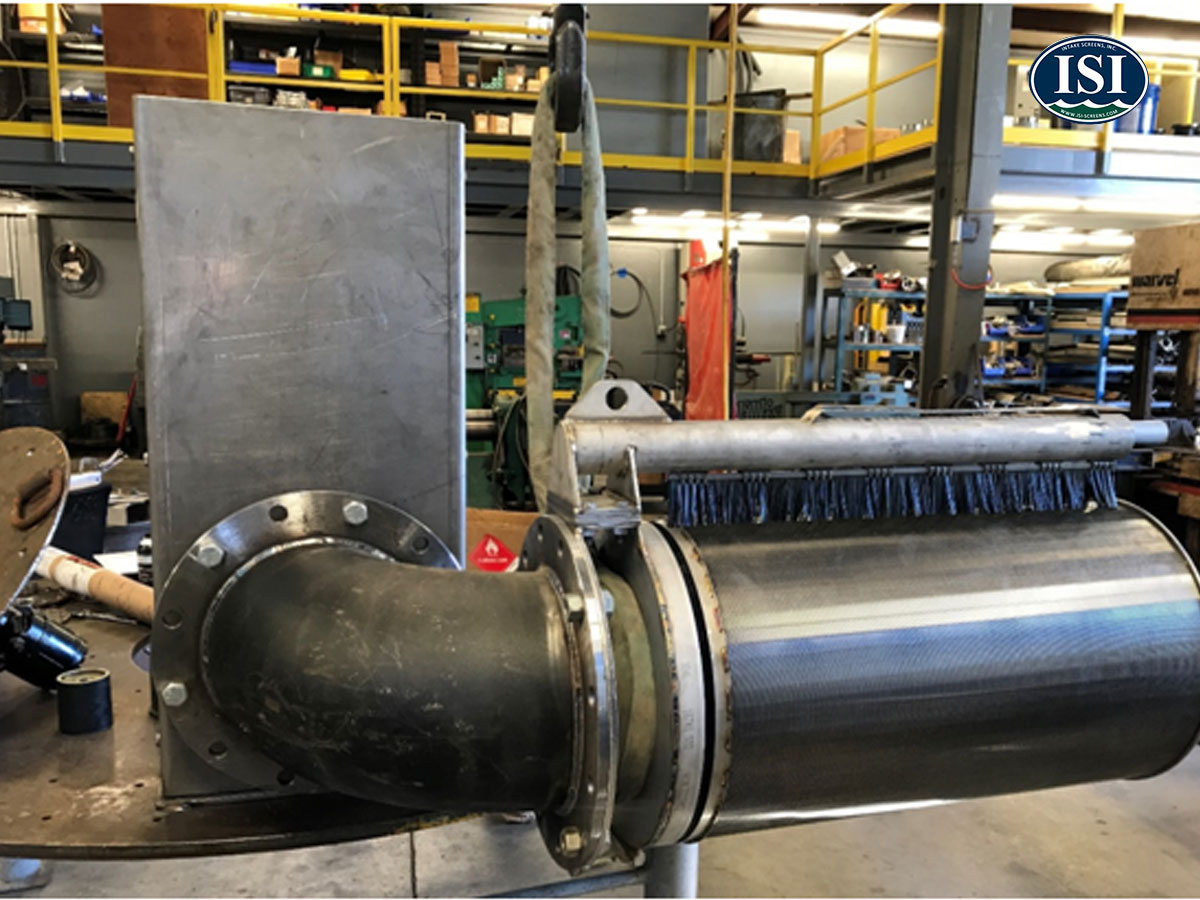

The Sears Property has a pumped irrigation intake located on the Shasta River in Siskiyou County, CA. ISI provided a D18-30TA-F screen for the project to meet state and federal fish protection criteria. The screen unit consists of a wedge wire cylinder, flanged docking connection, suction pipe, turbine drive system, and an external brush. The wedge wire cylinder is 18 inches (457 mm) in diameter and 30 inches (762 mm) in length. The total wedge wire screen area is 11 square feet (1.0 m2), resulting in an average approach velocity of less than 0.33 fps (10 cm/s) at a maximum flow rate of 3 cfs (1.9 MGD; 305 m3/h).

The screen unit has an internal turbine blade coupled to a high-reduction gearbox that slowly rotates the wedge wire cylinder screen as water flows through the screen and suction pipe. The screen has an external brush that cleans the surface as the cylinder rotates. The screen unit has a 12-inch (305 mm) flanged connection to a 90-degree elbow which connects to a docking plate. The docking plate is equipped with guide rails to slide the screen unit into place over the intake opening for easy installation and removal. The overall weight of the screen unit, elbow, and docking plate is approximately 475 pounds (1,047 kg).

The wedge wire screen, suction pipe, brush arm, and flange are fabricated of type 304 stainless steel while the 90-degree elbow and docking plate are made from A36 carbon steel and hot dipped galvanized. The carbon steel gearbox is epoxy coated and electrically insulated from dissimilar metals with fiberglass gaskets and washers. A sacrificial magnesium anode is attached to the turbine drive assembly for additional cathodic protection.

Benefit of ISI System

ISI's brush-cleaned cylindrical drum screen system provides the following key advantages at this site:

- The brush cleaning system ensures that the screen surface will remain free of debris and fouling organisms and therefore maintain compliance with state and federal fish protection requirements and reliably source water to the facility;

- The turbine drive screen allowed the facility to install an actively cleaned screen without providing power to the intake;

- The 90-degree elbow and docking plate allow the screen to take advantage of river sweeping flows by orienting the screen parallel with river flow when the screen is in the operational position and provides a quick and efficient method to remove and install the system when needed.

Owner:

Sears Property

Engineer(s):

Vestra

General Contractor:

GS Black, Inc.

Location:

Shasta River, Siskiyou County, CA

Year Installed:

2018

Slot Size:

1.75mm

Screen Model:

D18-30TA-R

Drive System:

Turbine

Industry:

Irrigation

Water Body:

Stream/River

Flow Rate:

3 cfs (1.9 MGD; 305 m3/h)

Screen Type:

Drum Screens (single cylinder)

Retrieval Systems:

Fixed Flange Connection

Number of Screens:

1

Back To All Projects

Back To All Projects