Houston Northeast Water Purification Plant

Houston Northeast Water Purification Plant

Background:

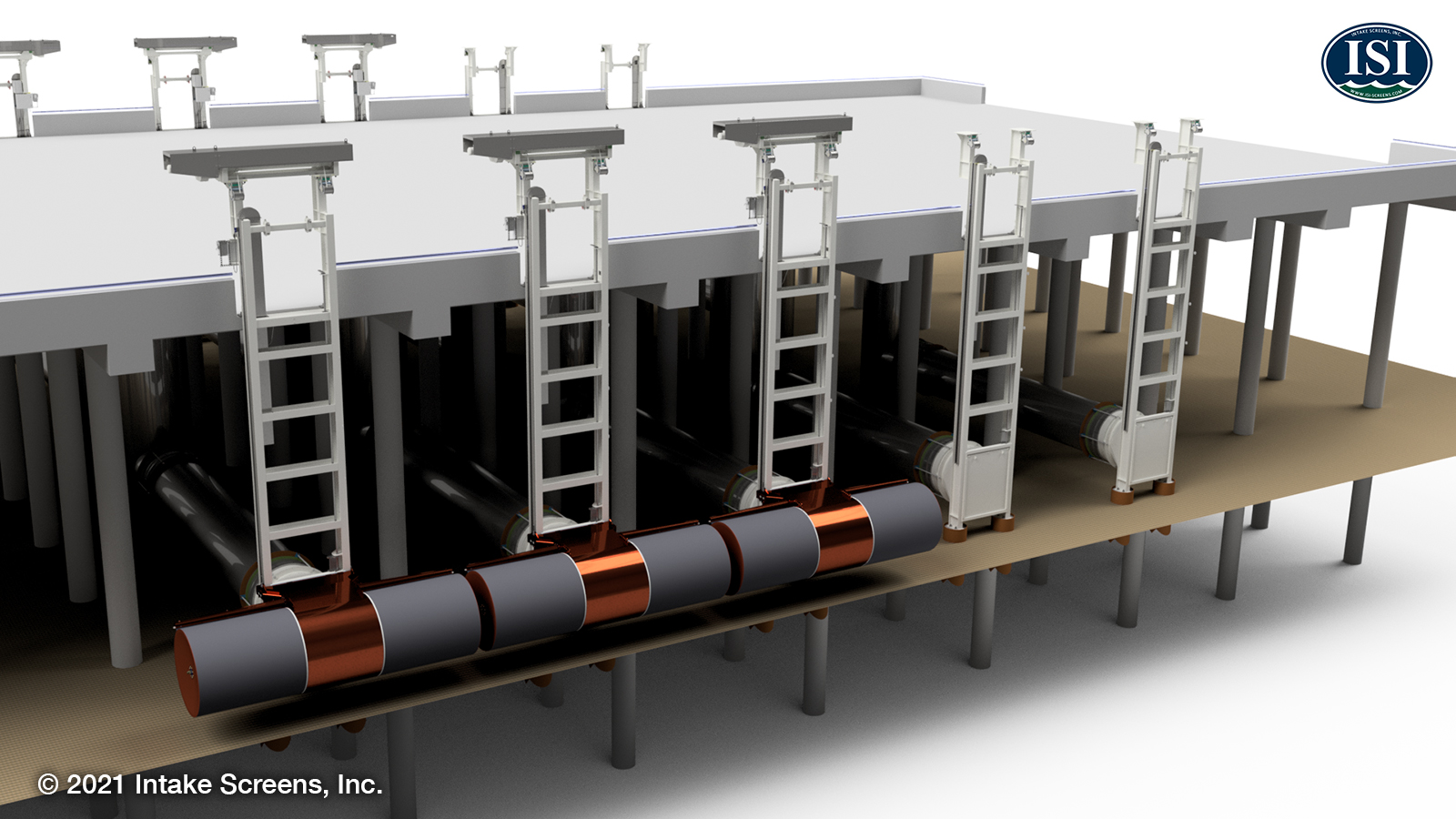

The Houston Northeast Water Purification Plant draws water from upstream of a dam near the south end of the west shore of the 12,000-acre (48.6 km2) Lake Houston. The plant treats Lake Houston water and turns it into drinking water for parts of Harris, Fort Bend, and surrounding areas. A new treatment facility is located next to the existing purification plant and sized to contribute an additional 495 cfs (320 MGD;50,472 m³/h) of treated water capacity to the current 80 MGD (123.8 cfs;12,618 m³/h). Included in the new plant is a new intake pump station which is located approximately 900 feet (274 meter) from the shore of the Lake. This advanced facility uses mechanical brush cleaned wedge wire T screens to withdraw water from Lake Houston which is then delivered through two 108-inch (274.3-cm) diameter pipes to the Water Purification Plant located about 1.5 miles (2.4 km) away.

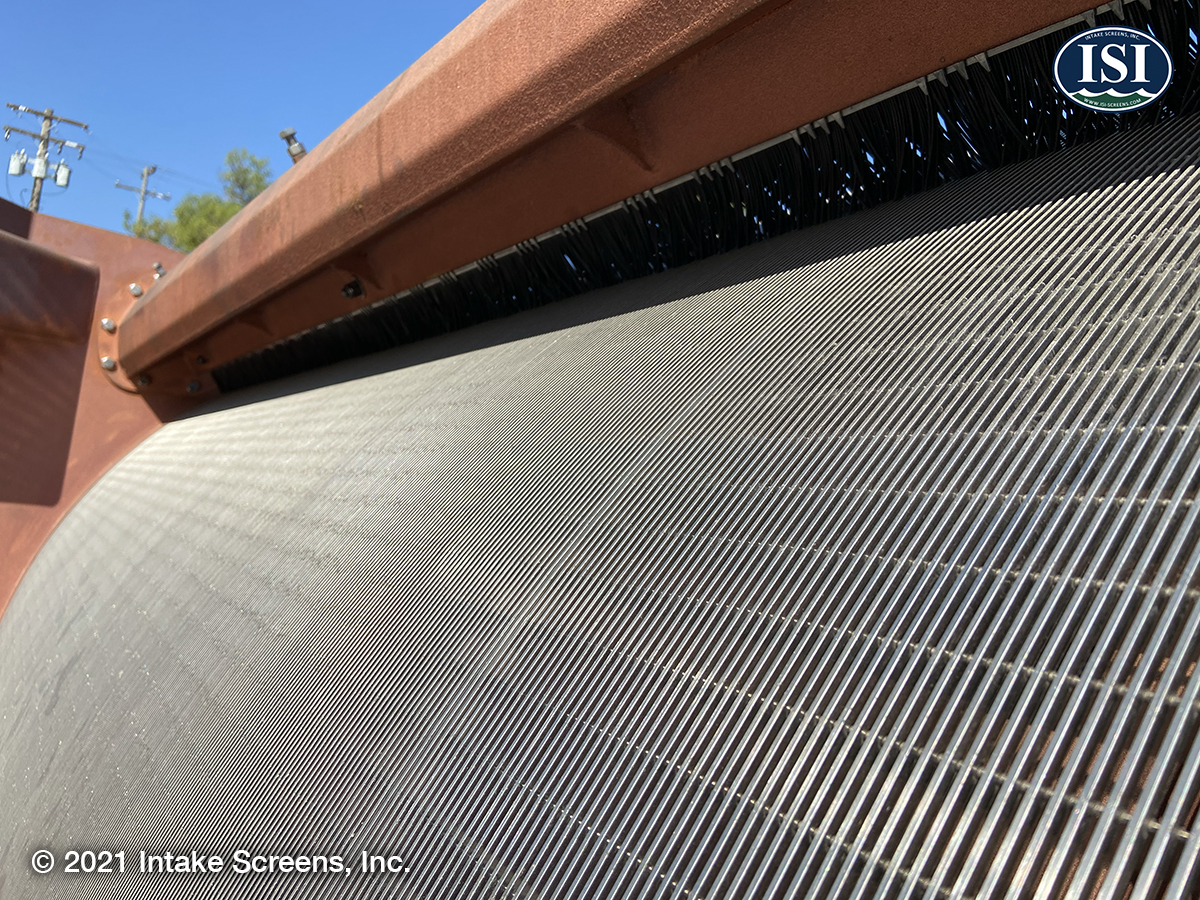

ISI designed and fabricated six custom T screens for the Houston Northeast Water Purification Plant. The two wedge wire cylinders on each T screen are 83-inches (210.8 cm) in diameter and 100-inches (254-cm) long and include an electrically driven internal and external brush cleaning system. Each T83-100EA-R screen has a total screen surface area of approximately 362 square feet (33.6 m2) and can divert approximately 77 MGD (119.1 cfs;12,144.9 m³/h) at a 0.5 fps (0.15 m/s) through-slot velocity. Stainless steel was used exclusively for all screen fabrications and hardware excluding the drive assembly which is epoxy coated carbon steel. The wedge wire screen material utilizes a 3.175-mm slot opening resulting in a 50% open area. The interior surfaces of the central manifold, including the internal brush trough, and the interior and exterior surfaces of the suction pipe are coated with thermal copper spray to prevent colonization of the non-brush cleaned surfaces with invasive mussels and other fouling organisms.

Each T screen is mounted on a retrieval track that allows it to be raised and lowered for inspection and maintenance using an electric controlled hoist. At the base of each track are foot plates that allow the track system to be supported by two 30-inch (76.2 cm) base piles above the foot plates. A docking inlet is built into the structure with a removable trash rack. A total of ten retrieval tracks were built to allow for future expansion from the current six T screens to 10.

Benefit of ISI System

ISI's brush-cleaned retractable T screen system provides the following key advantages at this site:

- The brush cleaning system ensures that the screen surface will remain free of debris and fouling organisms and therefore maintain compliance with through-screen velocity requirements and reliably source water to the facility;

- The retrievable screen with trash rack design allows the screens to be raised out of the lakefor inspection and maintenance without allowing large debris to enter the intake;

- The thermal copper spray ensure that the non-brush cleaned screen surfaces will remain free of debris and fouling organisms including invasive mussels;The cylindrical screen shape provides a large screen surface area in a small project footprint.

Owner:

Houston Northeast Water Purification Plant

Engineer(s):

Jacobs

General Contractor:

McCarthy Building Companies, Inc.

Location:

Houston Lake, Houston, TX

Year Installed:

2021

Slot Size:

3.175 mm

Screen Model:

T83-100EA-R

Drive System:

Electric

Industry:

Municipal

Water Body:

Pond

Flow Rate:

495 cfs (320 MGD;50,472 m³/h)

Screen Type:

T Screens (dual cylinders)

Retrieval Systems:

Retrievable Vertical Track

Number of Screens:

10

Back To All Projects

Back To All Projects