Cedar Creek Municipal Intake

Cedar Creek Municipal Intake

Background:

Dallas Water Utilities (DWU) and the Tarrant Regional Water District (TRWD) together currently serve over 4 million residents in North Central Texas. When both agencies were planning their own individual water pipeline projects, they determined that the similarities in their routes provided opportunities for partnered finance, design, and construction. This partnership resulted in the development of the Integrated Pipeline (IPL) project. The IPL project is a raw water supply program that pulls water from the East Texas lakes and provides it to the residents of North Central Texas.

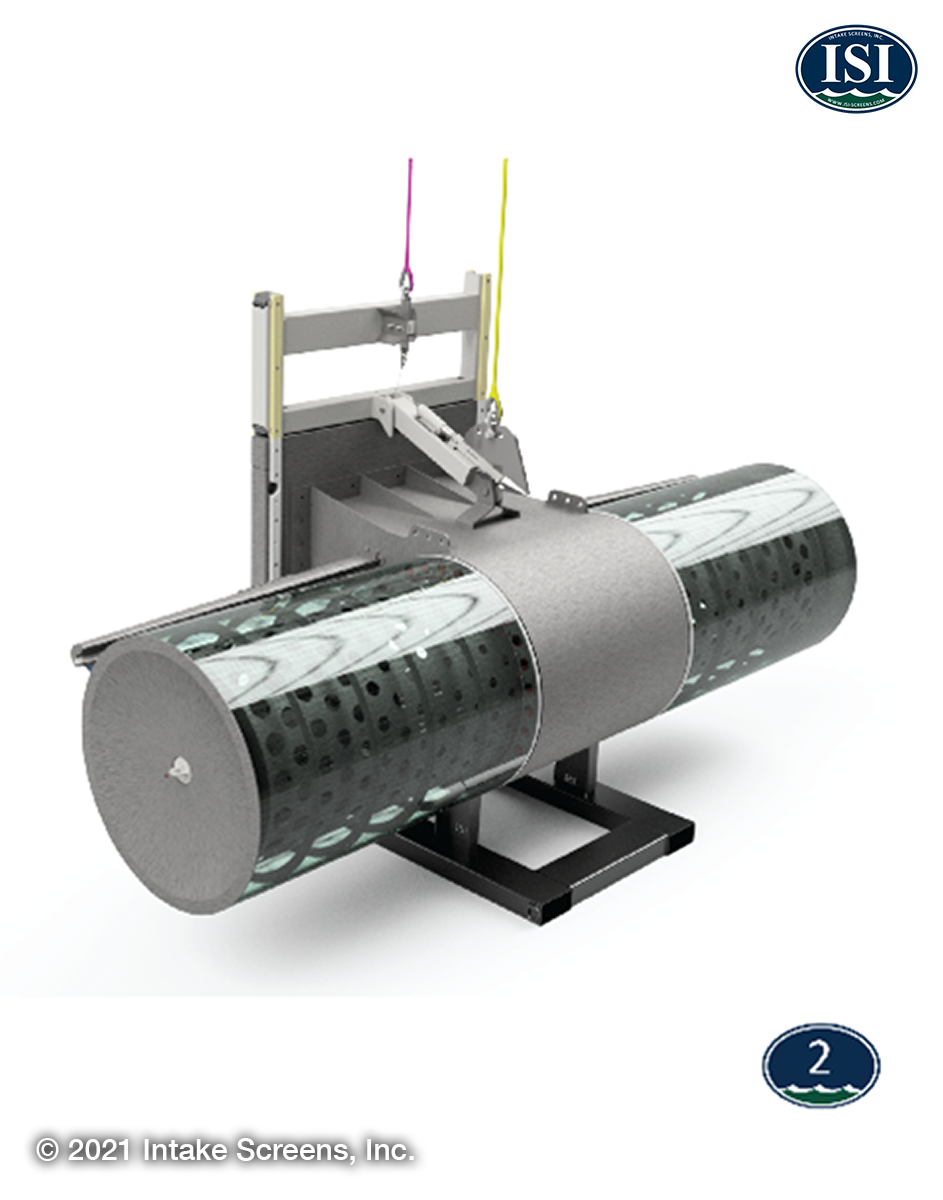

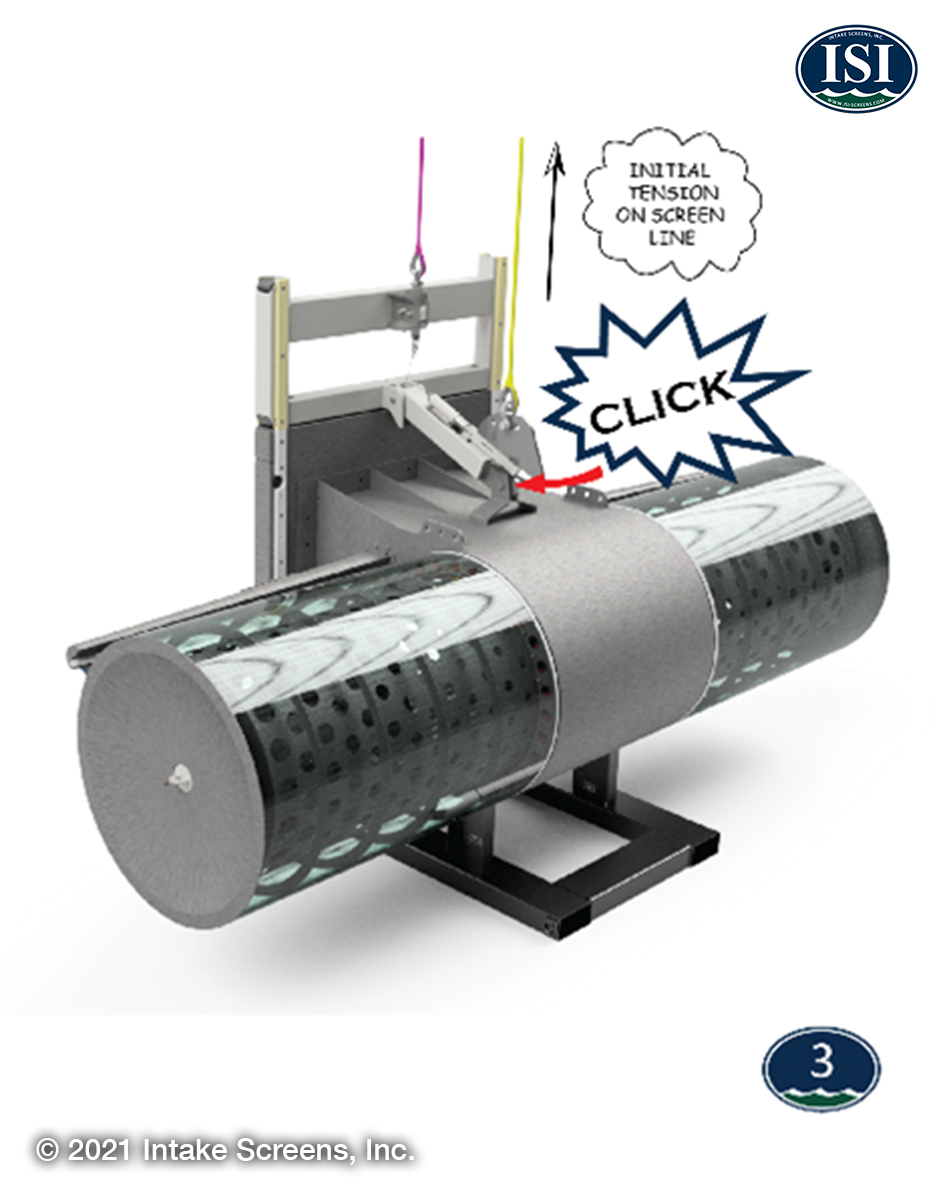

As part of the IPL upgrade, the Cedar Creek Lake Intake Pump Station was built. This 43-foot (13 m) deep concrete wet well structure hosts six intake T screens that supply raw water for seven vertical turbine pumps that are connected to a 108-inch-diameter (274.3 cm) pipeline. To meet fish protection and debris management requirements, ISI designed and fabricated nine (9)T60-84EB-Rself-cleaning cylindrical T screen units. Each T screen has two cylindrical wedge wire screens, each measuring 60 inches (152.4 cm) in diameter and 84-inches (213.4-cm) long. Six of the screens were installed on the bulkhead and three screens are stored as spares. Each T screen can divert a design flow of 71.5 cfs (46.2 MGD; 7,287 m³/h) with a maximum through-slot velocity of 0.5 fps (15.2 cm/s) resulting in a total system capacity of 429 cfs (277.2 MGD; 43,722m³/h) for six screens. Each T screen unit includes stainless steel wedge wire with 6.35 mm slots, two (2) submersible electric motors coupled with gear reducers, rotation sensors, internal and external brush cleaning systems, and a T manifold with lifting points.

This reservoir is known to have variable dissolved oxygen levels by water depth and season. Adjusting the screen height in the water column allows the operator to target more consistent dissolved oxygen levels to assist in chemical management at the downstream water treatment. ISI worked with Jacobs Engineering Group to develop an adjustable intake elevation screen system that includes bulkhead panels to allow for the intake opening to be adjusted up and down in the water column. To allow for easy removal and depth adjustment of the T screens, isolation panels are installed in a slot behind the screen guide rails to seal off the intake opening and keep fish and debris out of the opening when the screen is adjusted/removed. The variable height of the screen is then set by adding or removing blanking panels in the screen guide rail until the screen intake opening is at the desired height.

Benefit of ISI System

ISI's brush-cleaned retractable T screen system provides the following key advantages at this site:

- The brush cleaning system ensures that the screen surface will remain free of debris and fouling organisms and therefore maintain compliance with through-screen velocity requirements and reliably source water to the facility;

- The adjustable screen elevation system allows operators to withdraw from water depths with optimum dissolved oxygen concentrations;

- The cylindrical screen shape provides a large screen surface area in a small project footprint.

Owner:

Tarrant Regional Water District/ Dallas Water Utilities

Engineer(s):

Jacobs

General Contractor:

BAR Constructors

Location:

Cedar Creek Lake, Henderson, TX

Year Installed:

2021

Slot Size:

6.35 mm

Screen Model:

T60-84EB-R

Drive System:

Electric

Industry:

Municipal

Water Body:

Lake

Flow Rate:

429 cfs (277.2 MGD; 43,722 m³/h)

Screen Type:

T Screens (dual cylinders)

Retrieval Systems:

Retrievable Vertical Track

Number of Screens:

9

Back To All Projects

Back To All Projects