Cayuga Power Plant

Cayuga Power Plant

Background:

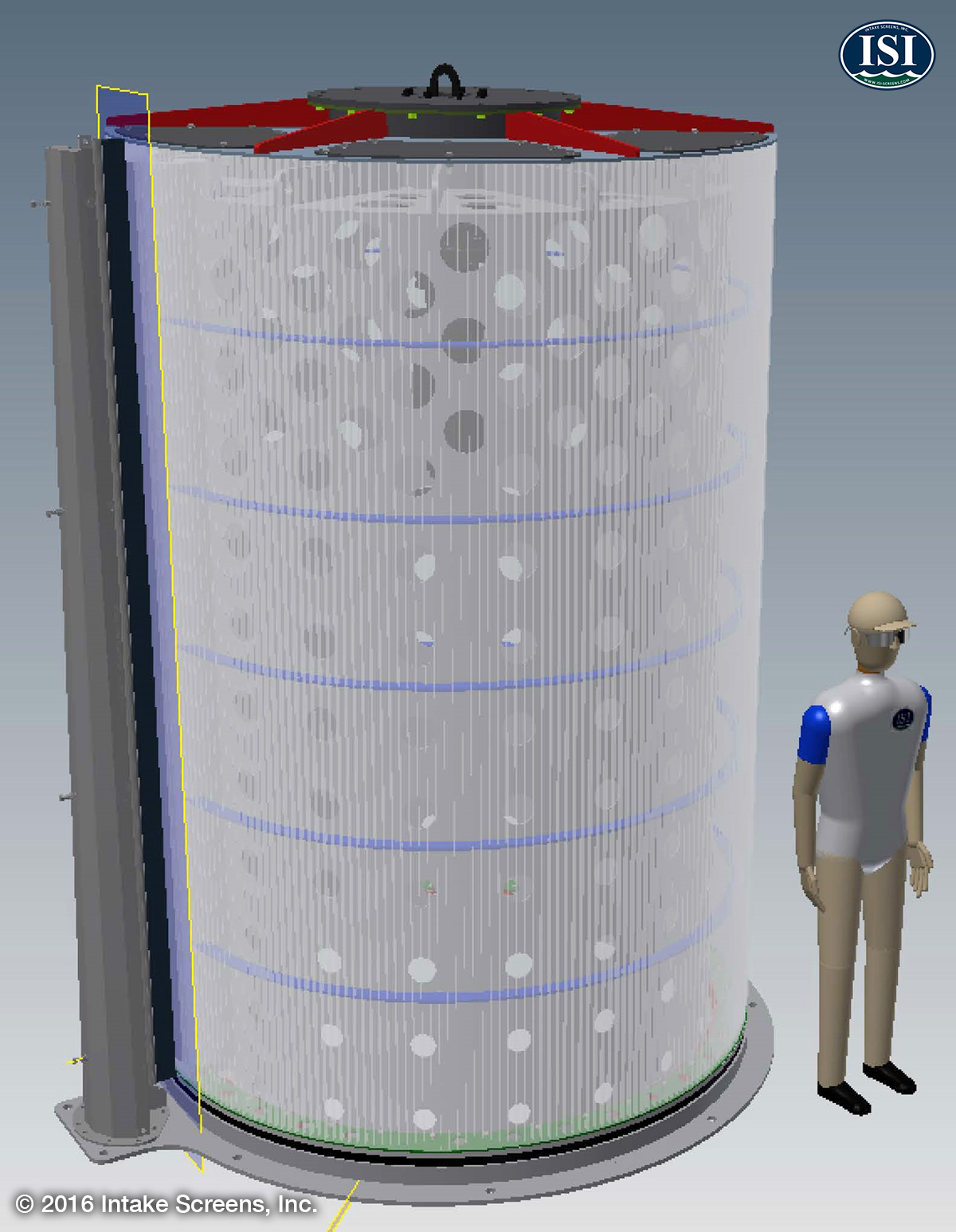

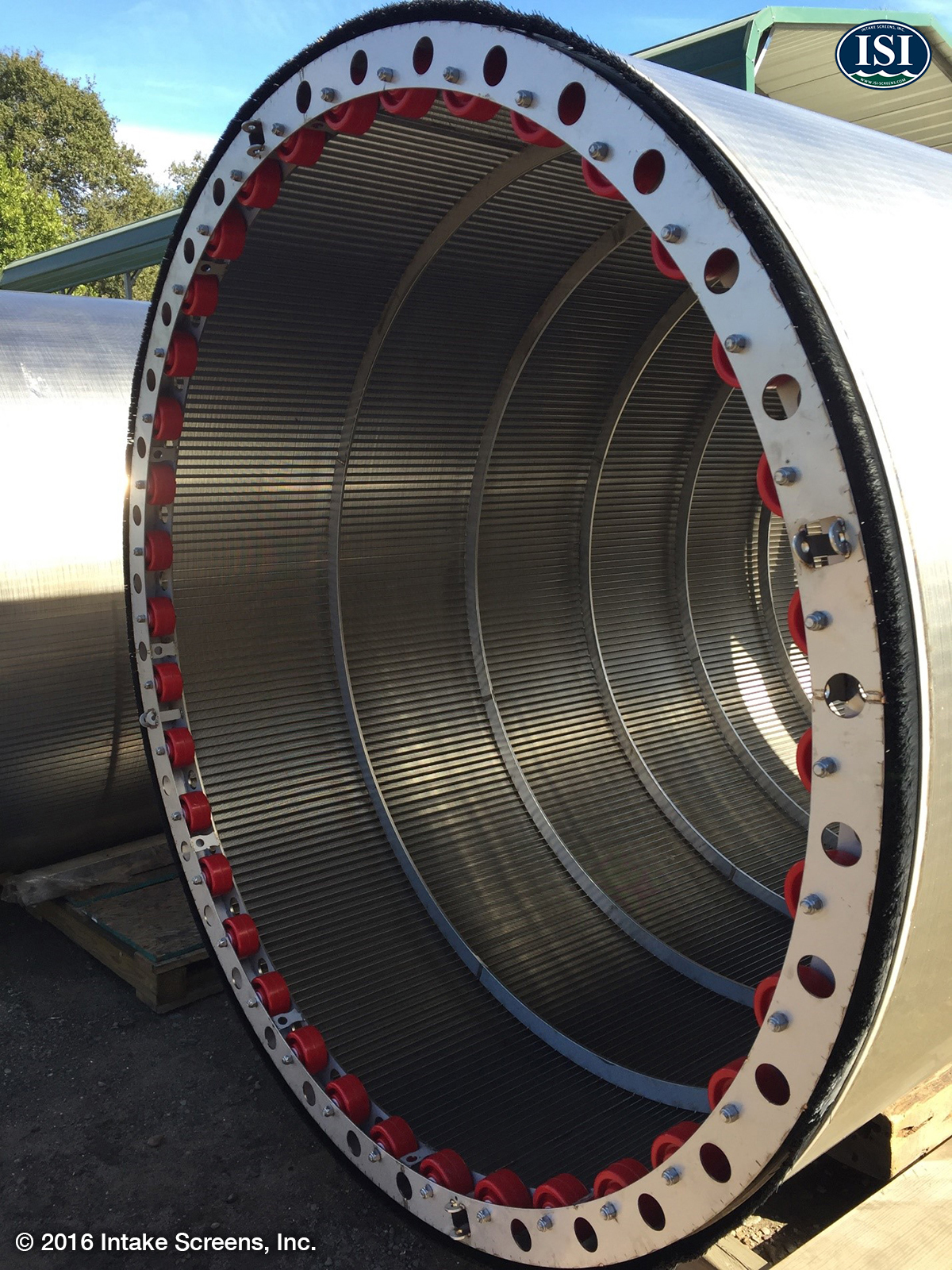

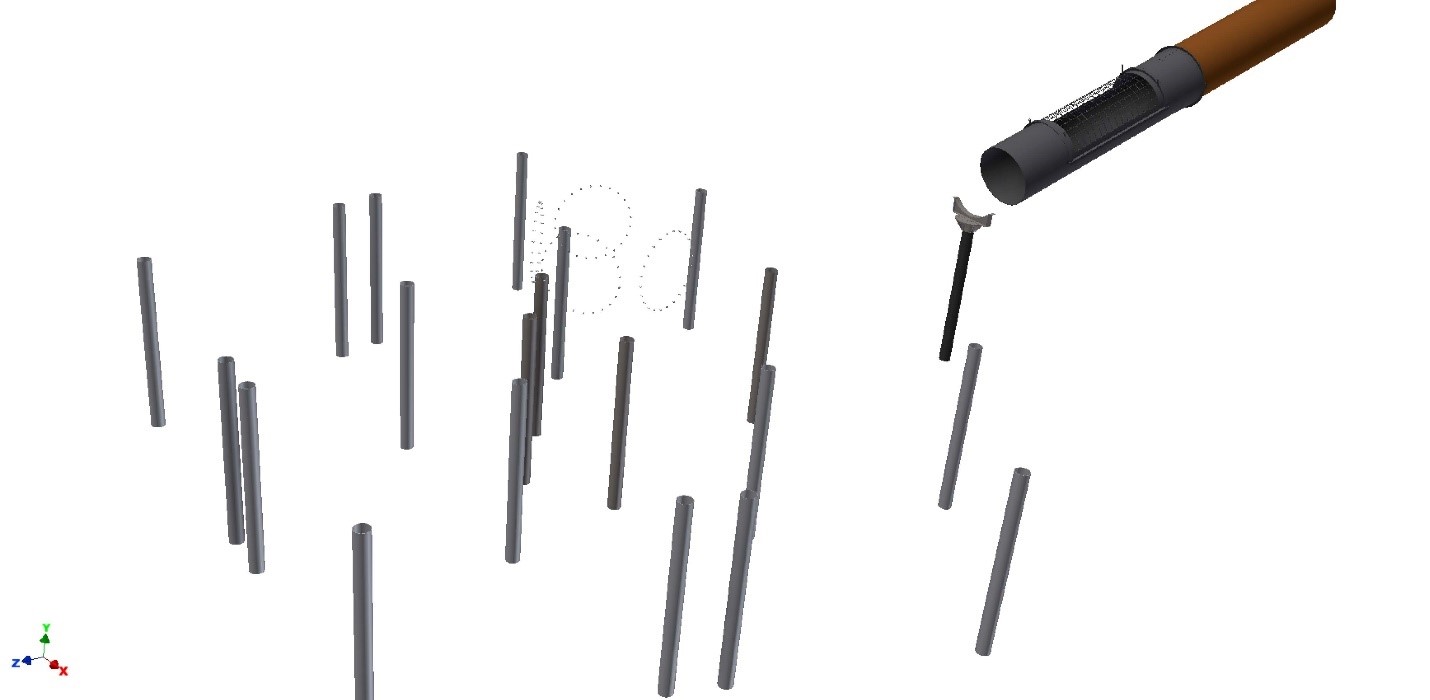

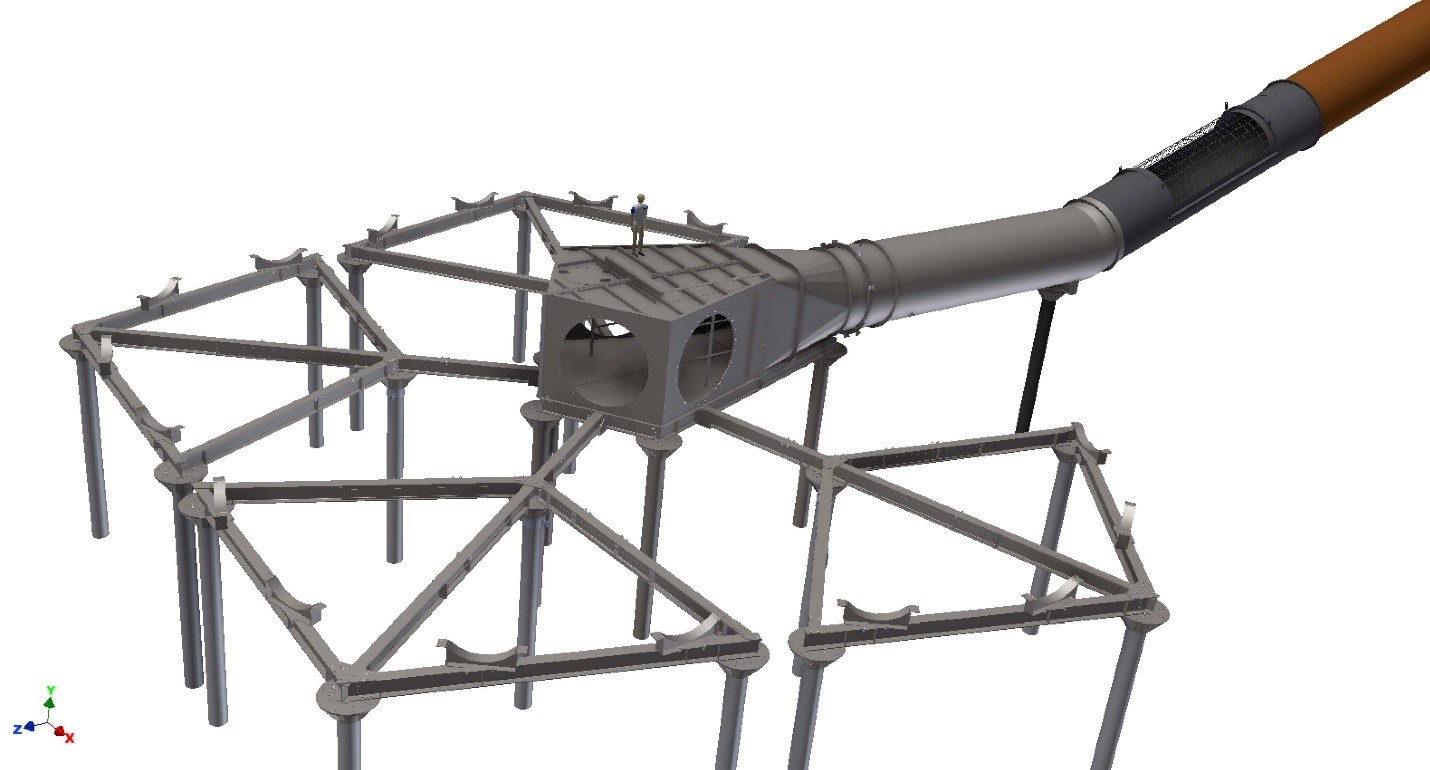

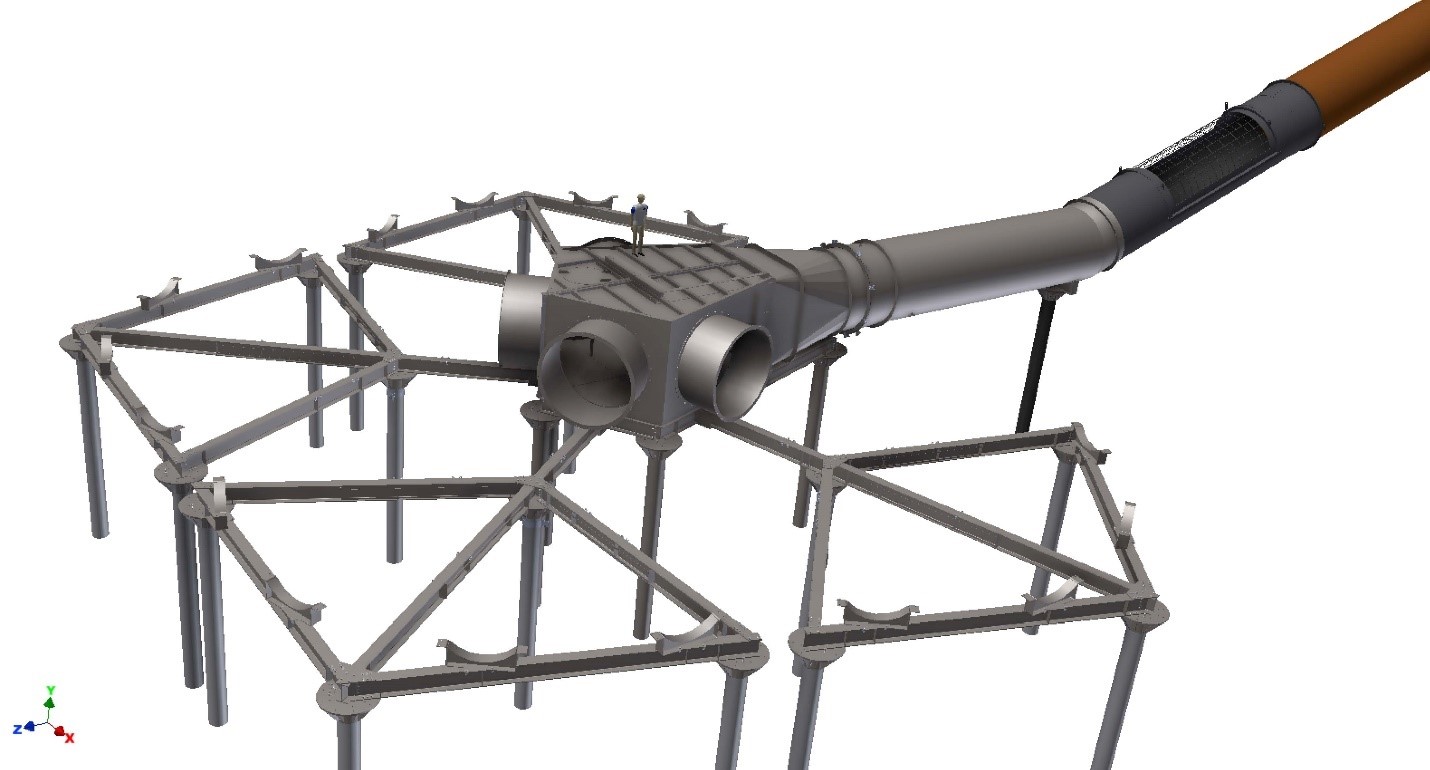

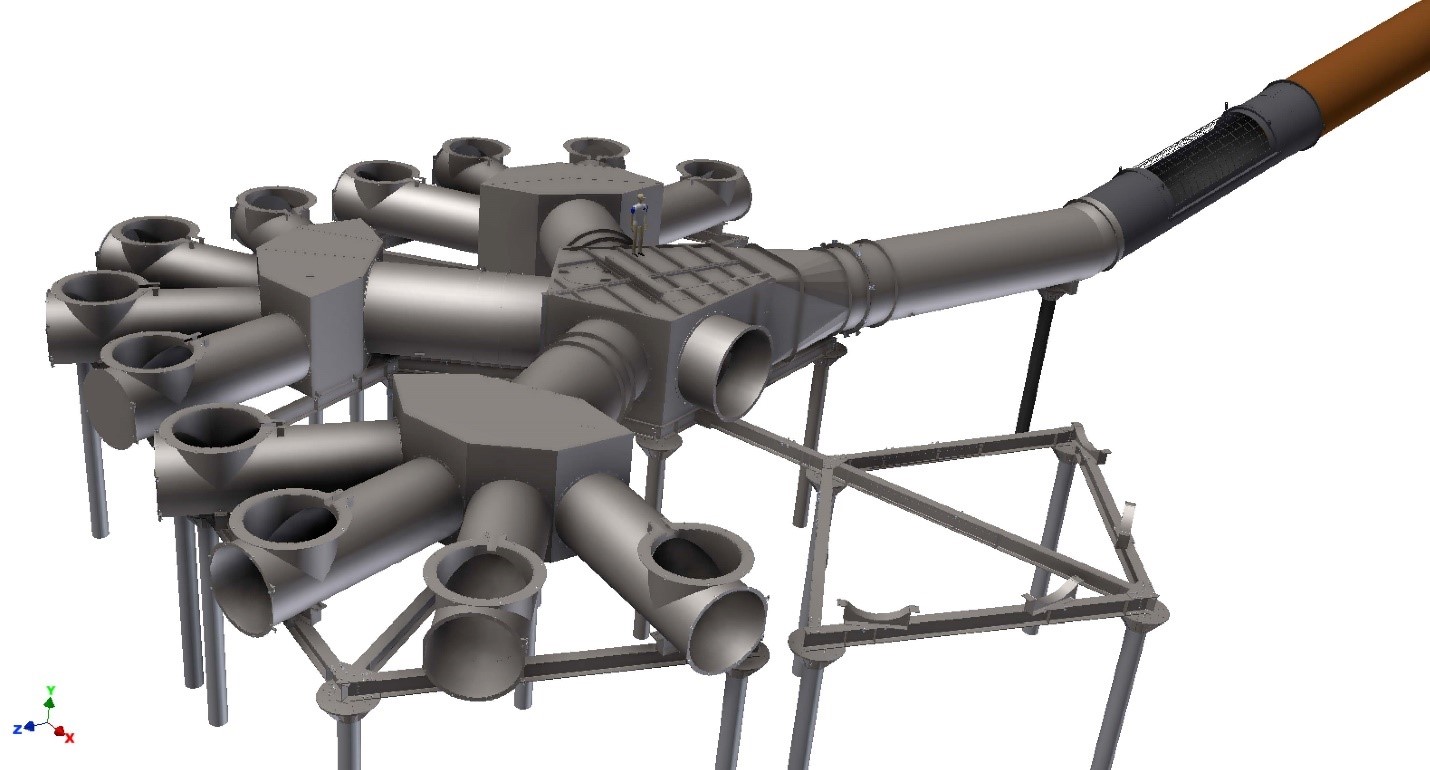

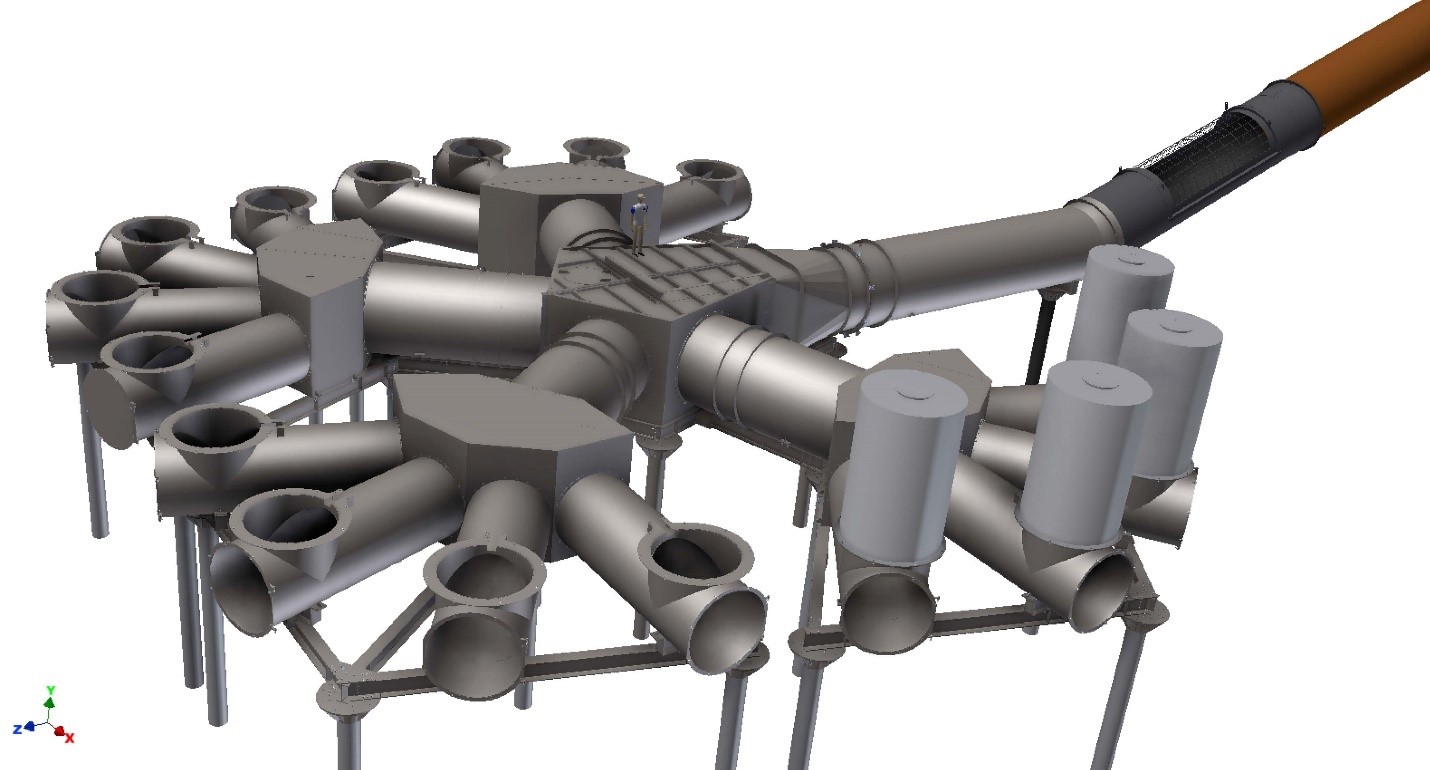

This 306 MW, 379 cfs (245 MGD; 38,643 m3/h) once-through cooled generating facility was required to install 0.75-mm slot size wedge wire screens with a 0.5 feet per second (15.24 cm/s) or less through-screen velocity to meet Clean Water Act Section 316(b) and New York State Department of Environmental Conservation (NYSDEC) CP-#52 Best Technology Available for Cooling Water Intake Structures requirements. The facility has an offshore, deep water intake located in Cayuga Lake where debris management challenges include zebra and quagga mussels, fishhook water fleas (Cercopagis pengoi), submerged aquatic vegetation (SAV), and algae. The project included an in-water pilot testing phase followed by design and fabrication of the full-scale screen array. This project is expected to be the largest 0.75-mm slot size wedge wire screen array installed anywhere in the world.

Benefit of ISI System

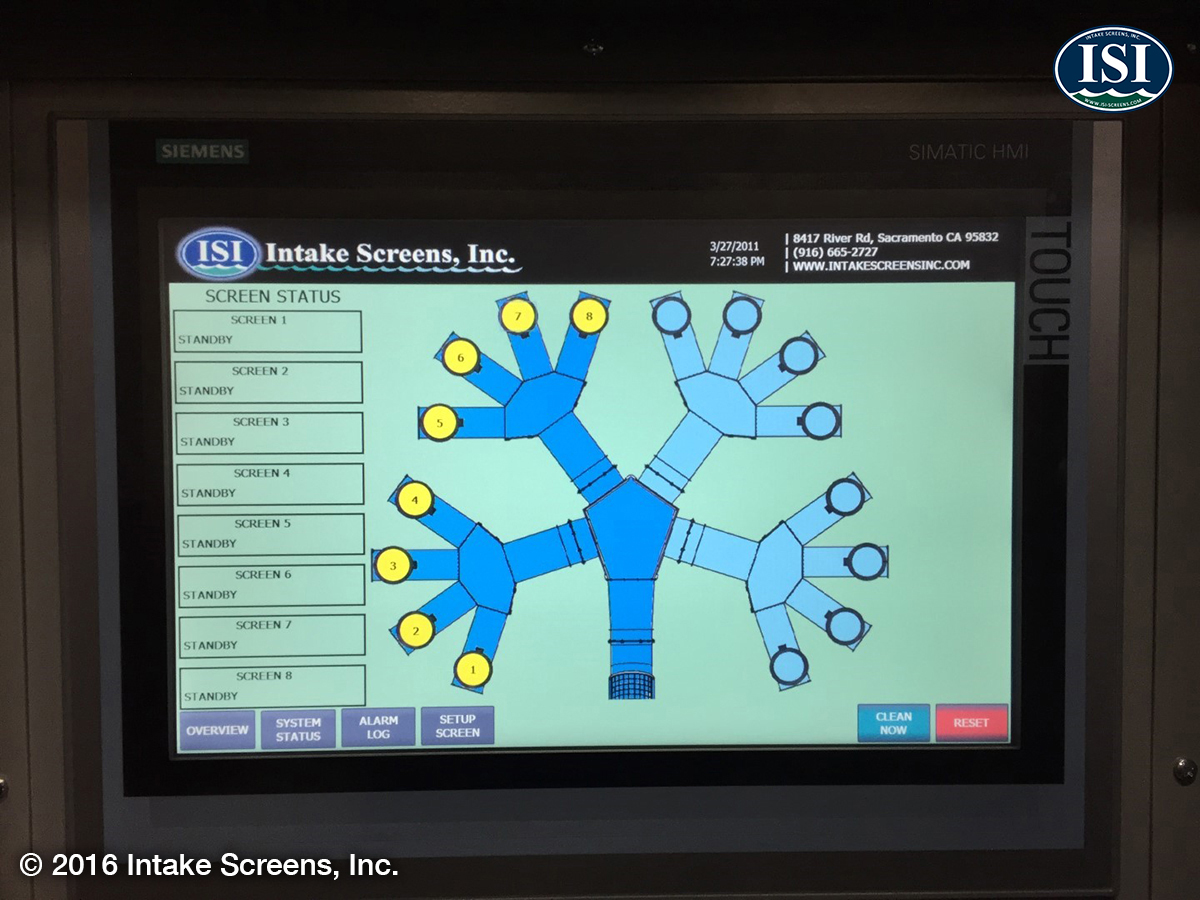

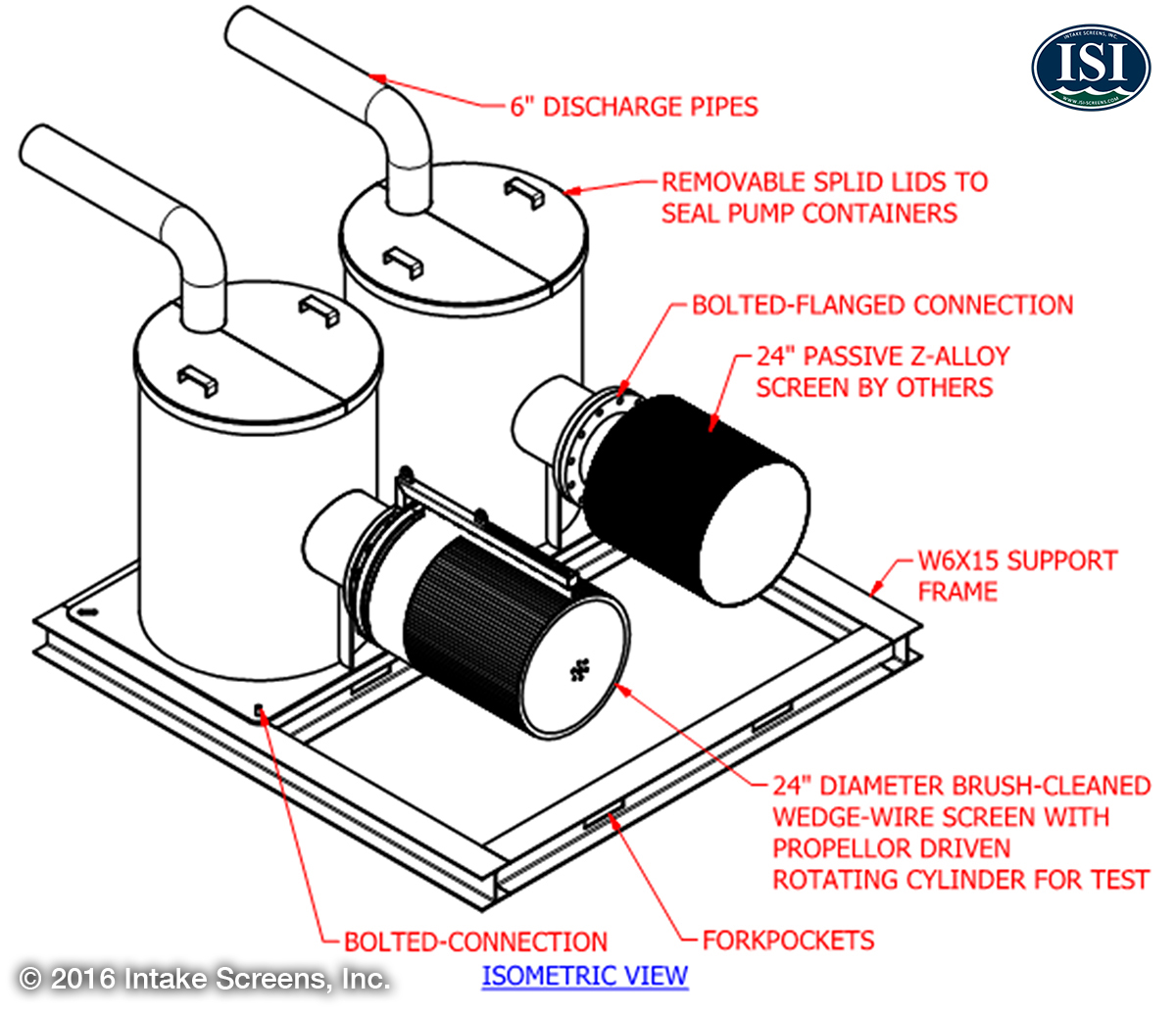

ISI’s screen design provided a mechanical brush-cleaned wedge wire screen array with 16 vertical drum screens that achieved an economic project footprint, efficient methods for screen maintenance, and minimize head loss (<3-inches). Pilot testing determined that the brush cleaned screen would have lower life-cycle costs than diver maintained passive copper-nickel screens and that silicon epoxy and copper coatings would be effective in maintaining non-brush cleaned surfaces. Overall, this facility was able to meet some of the most stringent fish protection requirements found anywhere in the world and reliably source water despite many challenging debris management issues.

Owner:

USNYPP

Engineer(s):

Makai Ocean Engineering

General Contractor:

Bidco Marine Group

Location:

Cayuga Lake, Lansing, NY

Year Installed:

2016

Slot Size:

0.75 mm

Screen Model:

D83-120EA-F

Drive System:

Electric

Industry:

Electrical Generation

Water Body:

Lake

Flow Rate:

379 cfs (245 MGD; 38,643 m3/h)

Screen Type:

Drum Screens (single cylinder)

Retrieval Systems:

Fixed Flange Connection

Number of Screens:

16

Back To All Projects

Back To All Projects